SKC inc. Lean Six Sigma Yellow Belt Certification Training Day Photo Diary

[vc_row css=”.vc_custom_1422341624235{margin: 30px 0px !important;padding: 30px 40px 20px !important;background-color: #ffffff !important;border: 1px solid #eeeeee !important;}” row_type=”row” use_row_as_full_screen_section=”no” type=”full_width” text_align=”left” background_image_as_pattern=”without_pattern”][vc_column width=”1/1″][vc_row_inner][vc_column_inner width=”1/3″][vc_column_text]

[/vc_column_text][/vc_column_inner][vc_column_inner width=”2/3″][vc_column_text]

Lean Six Sigma Yellow Belt Certification

Training Day

SEPTEMBER 12, 2014

A full day of discovery-driven, interactive training using the DMAIC framework. Adult-learning style with lots of hands-on team exercises to reinforce key concepts and tools.

A full day of discovery-driven, interactive training using the DMAIC framework. Adult-learning style with lots of hands-on team exercises to reinforce key concepts and tools.

Learning, Doing, Sharing, and Leading[/vc_column_text][/vc_column_inner][/vc_row_inner][vc_separator type=”normal” position=”center” color=”#cccccc” thickness=”1px” up=”20px” down=”20px”][vc_column_text]

Participants

40 participants from 19 organizations spend a day to learn problem solving and critical thinking. Our host is SKC Inc.[/vc_column_text][vc_row_inner][vc_column_inner width=”1/4″][vc_column_text]Manufacturing

- Beaver Manuf. Co.

- Bostik, Inc.

- Nyloboard, Inc.

- SPG Int’l, LLC

- SRG Global Inc.

[/vc_column_text][/vc_column_inner][vc_column_inner width=”1/4″][vc_column_text]Service

- Capes Prop. Management

- Innovation Partners

- Kelly Services

- McNaughton-McKay

- OmegaFi

- World Changers

[/vc_column_text][/vc_column_inner][vc_column_inner width=”1/4″][vc_column_text]Local Government

- Newton County Board of Commissioners

- Newton County Schools

- Newton County Economic Development

- Newton Count Water & Sewer Authority

[/vc_column_text][/vc_column_inner][vc_column_inner width=”1/4″][vc_column_text]Technology

- Black Box Corp.

- Cbeyond Comm.

[/vc_column_text][vc_column_text]Higher Education

- Georgia Piedmont Technical College

- Oxford College

[/vc_column_text][/vc_column_inner][/vc_row_inner][vc_separator type=”normal” position=”center” color=”#cccccc” thickness=”1px” up=”20px” down=”20px”][/vc_column][/vc_row][vc_row][vc_column width=”1/1″][vc_column_text]

Training Day at SKC Inc.

[/vc_column_text][TS_VCSC_Timeline_Container timeline_order=”asc” timeline_sort=”true” timeline_break=”600″ timeline_lazy=”true” timeline_count=”5″ timeline_trigger=”scroll” timeline_load=”Load More” timeline_title_color=”#7c7979″ timeline_description_align=”center” timeline_description_color=”#7c7979″ margin_top=”0″ margin_bottom=”0″][TS_VCSC_Timeline_Break color_background=”#ededed” title_text=”Morning Kick-Off” title_align=”center” title_color=”#7c7979″ content_align=”center” content_color=”#7c7979″][TS_VCSC_Timeline_Single full_width=”false” featured_media=”image” lightbox_featured=”true” page_rtl=”false” featured_youtube_related=”false” featured_youtube_play=”false” featured_dailymotion_play=”false” featured_vimeo_play=”false” featured_media_height=”height: 100%;” featured_media_width=”100″ featured_media_align=”center” title_align=”center” title_color=”#7c7979″ icon=”transparent” icon_color=”#7c7979″ tooltip_css=”false” tooltip_position=”ts-simptip-position-top” button_align=”center” button_width=”100″ button_type=”square” button_square=”ts-button-3d” button_rounded=”ts-button-3d ts-button-rounded” button_pill=”ts-button-3d ts-button-pill” button_circle=”ts-button-3d ts-button-circle” button_size=”ts-button-normal” button_wrapper=”false” button_text=”Read More” button_change=”false” button_color=”#666666″ button_font=”18″ lightbox_group=”true” lightbox_effect=”random” lightbox_backlight=”auto” lightbox_backlight_color=”#ffffff” featured_image=”15539″]Learning at SKC Inc.’s Executive Offices[/TS_VCSC_Timeline_Single][TS_VCSC_Timeline_Single full_width=”false” featured_media=”image” featured_image=”15540″ lightbox_featured=”true” page_rtl=”false” featured_youtube_related=”false” featured_youtube_play=”false” featured_dailymotion_play=”false” featured_vimeo_play=”false” featured_media_height=”height: 100%;” featured_media_width=”100″ featured_media_align=”center” title_align=”center” title_color=”#7c7979″ icon=”transparent” icon_color=”#7c7979″ tooltip_css=”false” tooltip_position=”ts-simptip-position-top” button_align=”center” button_width=”100″ button_type=”square” button_square=”ts-button-3d” button_rounded=”ts-button-3d ts-button-rounded” button_pill=”ts-button-3d ts-button-pill” button_circle=”ts-button-3d ts-button-circle” button_size=”ts-button-normal” button_wrapper=”false” button_text=”Read More” button_change=”false” button_color=”#666666″ button_font=”18″ lightbox_group=”true” lightbox_effect=”random” lightbox_backlight=”auto” lightbox_backlight_color=”#ffffff”]Riverwood Associates Knowledge Center[/TS_VCSC_Timeline_Single][TS_VCSC_Timeline_Break color_background=”#ededed” title_text=”Define” title_align=”center” title_color=”#7c7979″ content_align=”center” content_color=”#7c7979″][TS_VCSC_Timeline_Single full_width=”false” featured_media=”image” featured_image=”15542″ lightbox_featured=”true” page_rtl=”false” featured_youtube_related=”false” featured_youtube_play=”false” featured_dailymotion_play=”false” featured_vimeo_play=”false” featured_media_height=”height: 100%;” featured_media_width=”100″ featured_media_align=”center” title_text=”“What’s the Problem?”” title_align=”center” title_color=”#7c7979″ icon=”transparent” icon_color=”#7c7979″ tooltip_css=”false” tooltip_position=”ts-simptip-position-top” button_align=”center” button_width=”100″ button_type=”square” button_square=”ts-button-3d” button_rounded=”ts-button-3d ts-button-rounded” button_pill=”ts-button-3d ts-button-pill” button_circle=”ts-button-3d ts-button-circle” button_size=”ts-button-normal” button_wrapper=”false” button_text=”Read More” button_change=”false” button_color=”#666666″ button_font=”18″ lightbox_group=”true” lightbox_effect=”random” lightbox_backlight=”auto” lightbox_backlight_color=”#ffffff”]A lot of time is spent defining the problem using the opening scene from the movie “Moneyball”.

Jay Lanners, VP National Accounts at Black Box Corp., tries to get his arms around the problem.[/TS_VCSC_Timeline_Single][TS_VCSC_Timeline_Single full_width=”false” featured_media=”image” featured_image=”15544″ lightbox_featured=”true” page_rtl=”false” featured_youtube_related=”false” featured_youtube_play=”false” featured_dailymotion_play=”false” featured_vimeo_play=”false” featured_media_height=”height: 100%;” featured_media_width=”100″ featured_media_align=”center” title_text=”Voice of the Customer (VOC)” title_align=”center” title_color=”#7c7979″ icon=”ts-awesome-lightbulb-o” icon_color=”#7c7979″ tooltip_css=”false” tooltip_position=”ts-simptip-position-top” button_align=”center” button_width=”100″ button_type=”square” button_square=”ts-button-3d” button_rounded=”ts-button-3d ts-button-rounded” button_pill=”ts-button-3d ts-button-pill” button_circle=”ts-button-3d ts-button-circle” button_size=”ts-button-normal” button_wrapper=”false” button_text=”Read More” button_change=”false” button_color=”#666666″ button_font=”18″ lightbox_group=”true” lightbox_effect=”random” lightbox_backlight=”auto” lightbox_backlight_color=”#ffffff”]Jay can smile now. 🙂

Jay Lanners, VP National Accounts at Black Box Corp., tries to get his arms around the problem.[/TS_VCSC_Timeline_Single][TS_VCSC_Timeline_Single full_width=”false” featured_media=”image” featured_image=”15544″ lightbox_featured=”true” page_rtl=”false” featured_youtube_related=”false” featured_youtube_play=”false” featured_dailymotion_play=”false” featured_vimeo_play=”false” featured_media_height=”height: 100%;” featured_media_width=”100″ featured_media_align=”center” title_text=”Voice of the Customer (VOC)” title_align=”center” title_color=”#7c7979″ icon=”ts-awesome-lightbulb-o” icon_color=”#7c7979″ tooltip_css=”false” tooltip_position=”ts-simptip-position-top” button_align=”center” button_width=”100″ button_type=”square” button_square=”ts-button-3d” button_rounded=”ts-button-3d ts-button-rounded” button_pill=”ts-button-3d ts-button-pill” button_circle=”ts-button-3d ts-button-circle” button_size=”ts-button-normal” button_wrapper=”false” button_text=”Read More” button_change=”false” button_color=”#666666″ button_font=”18″ lightbox_group=”true” lightbox_effect=”random” lightbox_backlight=”auto” lightbox_backlight_color=”#ffffff”]Jay can smile now. 🙂

He understands how to develop a VOC.

The VOC turns those needs into Critical to Quality Requirements (CTQs) for creating the Yellow Belt Certification program.

Jay Lanners, VP National Accounts, Black Box Corp.[/TS_VCSC_Timeline_Single][TS_VCSC_Timeline_Single full_width=”false” featured_media=”image” featured_image=”15545″ lightbox_featured=”true” page_rtl=”false” featured_youtube_related=”false” featured_youtube_play=”false” featured_dailymotion_play=”false” featured_vimeo_play=”false” featured_media_height=”height: 100%;” featured_media_width=”100″ featured_media_align=”center” title_text=”SIPOC” title_align=”center” title_color=”#7c7979″ icon=”transparent” icon_color=”#7c7979″ tooltip_css=”false” tooltip_position=”ts-simptip-position-top” button_align=”center” button_width=”100″ button_type=”square” button_square=”ts-button-3d” button_rounded=”ts-button-3d ts-button-rounded” button_pill=”ts-button-3d ts-button-pill” button_circle=”ts-button-3d ts-button-circle” button_size=”ts-button-normal” button_wrapper=”false” button_text=”Read More” button_change=”false” button_color=”#666666″ button_font=”18″ lightbox_group=”true” lightbox_effect=”random” lightbox_backlight=”auto” lightbox_backlight_color=”#ffffff”]Eric Strickland shows us how to build a SIPOC (Suppliers, Inputs, Process, Outputs, Customers) for our Promotion-to-Certification process.

The 30,000 ft. process flow give us a head start for the detailed process mapping.

Eric Strickland, Product Development Manager, World Changers Church International[/TS_VCSC_Timeline_Single][TS_VCSC_Timeline_Single full_width=”true” featured_media=”image” featured_image=”15546″ lightbox_featured=”true” page_rtl=”false” featured_youtube_related=”false” featured_youtube_play=”false” featured_dailymotion_play=”false” featured_vimeo_play=”false” featured_media_height=”height: 100%;” featured_media_width=”100″ featured_media_align=”center” title_text=”Process Mapping” title_align=”center” title_color=”#7c7979″ icon=”transparent” icon_color=”#7c7979″ tooltip_css=”false” tooltip_position=”ts-simptip-position-top” button_align=”center” button_width=”100″ button_type=”square” button_square=”ts-button-3d” button_rounded=”ts-button-3d ts-button-rounded” button_pill=”ts-button-3d ts-button-pill” button_circle=”ts-button-3d ts-button-circle” button_size=”ts-button-normal” button_wrapper=”false” button_text=”Read More” button_change=”false” button_color=”#666666″ button_font=”18″ lightbox_group=”true” lightbox_effect=”random” lightbox_backlight=”auto” lightbox_backlight_color=”#ffffff”]Our first Team exercise. Toni Ciccarello, Director of Six Sigma, Planning & Supply Chain at SKC Inc., wants to understand the Promotion-to-Certification process for becoming a Lean Six Sigma Yellow Belt.[/TS_VCSC_Timeline_Single][TS_VCSC_Timeline_Single full_width=”false” featured_media=”image” featured_image=”15547″ lightbox_featured=”true” page_rtl=”false” featured_youtube_related=”false” featured_youtube_play=”false” featured_dailymotion_play=”false” featured_vimeo_play=”false” featured_media_height=”height: 100%;” featured_media_width=”100″ featured_media_align=”center” title_text=”Types of Process Maps: Activity Flow Map” title_align=”center” title_color=”#7c7979″ icon=”transparent” icon_color=”#7c7979″ tooltip_css=”false” tooltip_position=”ts-simptip-position-top” button_align=”center” button_width=”100″ button_type=”square” button_square=”ts-button-3d” button_rounded=”ts-button-3d ts-button-rounded” button_pill=”ts-button-3d ts-button-pill” button_circle=”ts-button-3d ts-button-circle” button_size=”ts-button-normal” button_wrapper=”false” button_text=”Read More” button_change=”false” button_color=”#666666″ button_font=”18″ lightbox_group=”true” lightbox_effect=”random” lightbox_backlight=”auto” lightbox_backlight_color=”#ffffff”]Dwayne Waller shows us an Activity Flow Map.[/TS_VCSC_Timeline_Single][TS_VCSC_Timeline_Single full_width=”false” featured_media=”image” featured_image=”15548″ lightbox_featured=”true” page_rtl=”false” featured_youtube_related=”false” featured_youtube_play=”false” featured_dailymotion_play=”false” featured_vimeo_play=”false” featured_media_height=”height: 100%;” featured_media_width=”100″ featured_media_align=”center” title_text=”Types of Process Maps: Activity Flow Map” title_align=”center” title_color=”#7c7979″ icon=”transparent” icon_color=”#7c7979″ tooltip_css=”false” tooltip_position=”ts-simptip-position-top” button_align=”center” button_width=”100″ button_type=”square” button_square=”ts-button-3d” button_rounded=”ts-button-3d ts-button-rounded” button_pill=”ts-button-3d ts-button-pill” button_circle=”ts-button-3d ts-button-circle” button_size=”ts-button-normal” button_wrapper=”false” button_text=”Read More” button_change=”false” button_color=”#666666″ button_font=”18″ lightbox_group=”true” lightbox_effect=”random” lightbox_backlight=”auto” lightbox_backlight_color=”#ffffff”]Tom Ambs describes a Swim-lane Map.[/TS_VCSC_Timeline_Single][TS_VCSC_Timeline_Single full_width=”false” featured_media=”image” featured_image=”15549″ lightbox_featured=”true” page_rtl=”false” featured_youtube_related=”false” featured_youtube_play=”false” featured_dailymotion_play=”false” featured_vimeo_play=”false” featured_media_height=”height: 100%;” featured_media_width=”100″ featured_media_align=”center” title_align=”center” title_color=”#7c7979″ icon_color=”#7c7979″ tooltip_css=”false” tooltip_position=”ts-simptip-position-top” button_align=”center” button_width=”100″ button_type=”square” button_square=”ts-button-3d” button_rounded=”ts-button-3d ts-button-rounded” button_pill=”ts-button-3d ts-button-pill” button_circle=”ts-button-3d ts-button-circle” button_size=”ts-button-normal” button_wrapper=”false” button_text=”Read More” button_change=”false” button_color=”#666666″ button_font=”18″ lightbox_group=”true” lightbox_effect=”random” lightbox_backlight=”auto” lightbox_backlight_color=”#ffffff” title_text=”Process Mapping is a Team Sport!” icon=”transparent”]Team 2 shows us how it’s done. Process Mapping can be insightful and fun!

Dwayne, Tim, Kris, Allison, Martha, Zoila, Lee[/TS_VCSC_Timeline_Single][TS_VCSC_Timeline_Break color_background=”#ededed” title_text=”Lunch Presentation” title_align=”center” title_color=”#7c7979″ content_align=”center” content_color=”#7c7979″][TS_VCSC_Timeline_Single full_width=”false” featured_media=”image” featured_image=”15550″ lightbox_featured=”true” page_rtl=”false” featured_youtube_related=”false” featured_youtube_play=”false” featured_dailymotion_play=”false” featured_vimeo_play=”false” featured_media_height=”height: 100%;” featured_media_width=”100″ featured_media_align=”center” title_align=”center” title_color=”#7c7979″ icon=”transparent” icon_color=”#7c7979″ tooltip_css=”false” tooltip_position=”ts-simptip-position-top” button_align=”center” button_width=”100″ button_type=”square” button_square=”ts-button-3d” button_rounded=”ts-button-3d ts-button-rounded” button_pill=”ts-button-3d ts-button-pill” button_circle=”ts-button-3d ts-button-circle” button_size=”ts-button-normal” button_wrapper=”false” button_text=”Read More” button_change=”false” button_color=”#666666″ button_font=”18″ lightbox_group=”true” lightbox_effect=”random” lightbox_backlight=”auto” lightbox_backlight_color=”#ffffff”]Toni Ciccarello describes SKC’s journey with Lean Six Sigma. It began in 2005 with a recognition by Chairman, Jong Hyon Chey, that to compete globally everyone in the company must embrace a common framework for process improvement – Lean Six Sigma.

Toni Ciccarello, Director of Six Sigma, Planning & Supply Chain, SKC Inc.[/TS_VCSC_Timeline_Single][TS_VCSC_Timeline_Single full_width=”false” featured_media=”image” lightbox_featured=”true” page_rtl=”false” featured_youtube_related=”false” featured_youtube_play=”false” featured_dailymotion_play=”false” featured_vimeo_play=”false” featured_media_height=”height: 100%;” featured_media_width=”100″ featured_media_align=”center” title_align=”center” title_color=”#7c7979″ icon=”ts-awesome-lightbulb-o” icon_color=”#7c7979″ tooltip_css=”false” tooltip_position=”ts-simptip-position-top” button_align=”center” button_width=”100″ button_type=”square” button_square=”ts-button-3d” button_rounded=”ts-button-3d ts-button-rounded” button_pill=”ts-button-3d ts-button-pill” button_circle=”ts-button-3d ts-button-circle” button_size=”ts-button-normal” button_wrapper=”false” button_text=”Read More” button_change=”false” button_color=”#666666″ button_font=”18″ lightbox_group=”true” lightbox_effect=”random” lightbox_backlight=”auto” lightbox_backlight_color=”#ffffff” featured_image=”15551″ title_text=”What does Toni do in her spare time?”]Peter Sherman, Instructor, and Toni Ciccarello share a light-hearted moment.

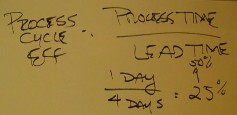

One of Toni’s hobbies is deer hunting with her husband. She also likes to read process improvement books during the hunts![/TS_VCSC_Timeline_Single][TS_VCSC_Timeline_Break color_background=”#ededed” title_text=”Measure” title_align=”center” title_color=”#7c7979″ content_align=”center” content_color=”#7c7979″][TS_VCSC_Timeline_Single full_width=”false” featured_media=”image” featured_image=”15552″ lightbox_featured=”true” page_rtl=”false” featured_youtube_related=”false” featured_youtube_play=”false” featured_dailymotion_play=”false” featured_vimeo_play=”false” featured_media_height=”height: 100%;” featured_media_width=”100″ featured_media_align=”center” title_align=”center” title_color=”#7c7979″ icon=”transparent” icon_color=”#7c7979″ tooltip_css=”false” tooltip_position=”ts-simptip-position-top” button_align=”center” button_width=”100″ button_type=”square” button_square=”ts-button-3d” button_rounded=”ts-button-3d ts-button-rounded” button_pill=”ts-button-3d ts-button-pill” button_circle=”ts-button-3d ts-button-circle” button_size=”ts-button-normal” button_wrapper=”false” button_text=”Read More” button_change=”false” button_color=”#666666″ button_font=”18″ lightbox_group=”true” lightbox_effect=”random” lightbox_backlight=”auto” lightbox_backlight_color=”#ffffff” title_text=”Calculating Lean Metrics”] Samantha calculates the Process Cycle Efficiency to be 25%.

Samantha calculates the Process Cycle Efficiency to be 25%.

Although the process can be considered “Lean”, Samantha’s real takeaway is that 75% of the time the customer is waiting for their certificate![/TS_VCSC_Timeline_Single][TS_VCSC_Timeline_Single full_width=”false” featured_media=”image” featured_image=”15555″ lightbox_featured=”true” page_rtl=”false” featured_youtube_related=”false” featured_youtube_play=”false” featured_dailymotion_play=”false” featured_vimeo_play=”false” featured_media_height=”height: 100%;” featured_media_width=”100″ featured_media_align=”center” title_align=”center” title_color=”#7c7979″ icon=”transparent” icon_color=”#7c7979″ tooltip_css=”false” tooltip_position=”ts-simptip-position-top” button_align=”center” button_width=”100″ button_type=”square” button_square=”ts-button-3d” button_rounded=”ts-button-3d ts-button-rounded” button_pill=”ts-button-3d ts-button-pill” button_circle=”ts-button-3d ts-button-circle” button_size=”ts-button-normal” button_wrapper=”false” button_text=”Read More” button_change=”false” button_color=”#666666″ button_font=”18″ lightbox_group=”true” lightbox_effect=”random” lightbox_backlight=”auto” lightbox_backlight_color=”#ffffff” title_text=”Why is Allison so sad?”]Allison Woodard is sad because she calculates the Cost of Doing Nothing (CODN) for the Shipping exercise is $143,000 per year!

That’s a lot of MUDA!

Allison Woodard, Business Engagement Coordinator, Newton County School System[/TS_VCSC_Timeline_Single][TS_VCSC_Timeline_Single full_width=”false” featured_media=”image” featured_image=”15556″ lightbox_featured=”true” page_rtl=”false” featured_youtube_related=”false” featured_youtube_play=”false” featured_dailymotion_play=”false” featured_vimeo_play=”false” featured_media_height=”height: 100%;” featured_media_width=”100″ featured_media_align=”center” title_text=”Fishing for Root Causes” title_align=”center” title_color=”#7c7979″ icon=”transparent” icon_color=”#7c7979″ tooltip_css=”false” tooltip_position=”ts-simptip-position-top” button_align=”center” button_width=”100″ button_type=”square” button_square=”ts-button-3d” button_rounded=”ts-button-3d ts-button-rounded” button_pill=”ts-button-3d ts-button-pill” button_circle=”ts-button-3d ts-button-circle” button_size=”ts-button-normal” button_wrapper=”false” button_text=”Read More” button_change=”false” button_color=”#666666″ button_font=”18″ lightbox_group=”true” lightbox_effect=”random” lightbox_backlight=”auto” lightbox_backlight_color=”#ffffff”]The group wants to know the possible causes that Lean Six Sigma might not be fully embraced in organizations.

We learn to use a Fishbone Diagram in conjunction with the 5 Whys.[/TS_VCSC_Timeline_Single][TS_VCSC_Timeline_Single full_width=”false” featured_media=”slider” lightbox_featured=”true” page_rtl=”false” featured_youtube_related=”false” featured_youtube_play=”false” featured_dailymotion_play=”false” featured_vimeo_play=”false” featured_media_height=”height: 100%;” featured_media_width=”100″ featured_media_align=”center” title_align=”center” title_color=”#7c7979″ icon=”transparent” icon_color=”#7c7979″ tooltip_css=”false” tooltip_position=”ts-simptip-position-top” button_align=”center” button_width=”100″ button_type=”square” button_square=”ts-button-3d” button_rounded=”ts-button-3d ts-button-rounded” button_pill=”ts-button-3d ts-button-pill” button_circle=”ts-button-3d ts-button-circle” button_size=”ts-button-normal” button_wrapper=”false” button_text=”Read More” button_change=”false” button_color=”#666666″ button_font=”18″ lightbox_group=”true” lightbox_effect=”random” lightbox_backlight=”auto” lightbox_backlight_color=”#ffffff” featured_slider=”15558,15560,15559″ title_text=”Connecting the Dots”] Chad Walker, Principal / CEO of The Newton College Career Academy, attempts to connect the dots.

Chad Walker, Principal / CEO of The Newton College Career Academy, attempts to connect the dots.

Mr. Walker thinks “outside the box”! 🙂

[/TS_VCSC_Timeline_Single][TS_VCSC_Timeline_Break color_background=”#ededed” title_text=”End of The Day” title_align=”center” title_color=”#7c7979″ content_align=”center” content_color=”#7c7979″][TS_VCSC_Timeline_Single full_width=”false” featured_media=”image” featured_image=”15561″ lightbox_featured=”true” page_rtl=”false” featured_youtube_related=”false” featured_youtube_play=”false” featured_dailymotion_play=”false” featured_vimeo_play=”false” featured_media_height=”height: 100%;” featured_media_width=”100″ featured_media_align=”center” title_align=”center” title_color=”#7c7979″ icon=”transparent” icon_color=”#7c7979″ tooltip_css=”false” tooltip_position=”ts-simptip-position-top” button_align=”center” button_width=”100″ button_type=”square” button_square=”ts-button-3d” button_rounded=”ts-button-3d ts-button-rounded” button_pill=”ts-button-3d ts-button-pill” button_circle=”ts-button-3d ts-button-circle” button_size=”ts-button-normal” button_wrapper=”false” button_text=”Read More” button_change=”false” button_color=”#666666″ button_font=”18″ lightbox_group=”true” lightbox_effect=”random” lightbox_backlight=”auto” lightbox_backlight_color=”#ffffff” title_text=”“Aha” Moments”]At the end of the day, participants write down their “Aha” moments about what they learned.[/TS_VCSC_Timeline_Single][TS_VCSC_Timeline_Single full_width=”false” featured_media=”image” featured_image=”15562″ lightbox_featured=”true” page_rtl=”false” featured_youtube_related=”false” featured_youtube_play=”false” featured_dailymotion_play=”false” featured_vimeo_play=”false” featured_media_height=”height: 100%;” featured_media_width=”100″ featured_media_align=”center” title_align=”center” title_color=”#7c7979″ icon=”transparent” icon_color=”#7c7979″ tooltip_css=”false” tooltip_position=”ts-simptip-position-top” button_align=”center” button_width=”100″ button_type=”square” button_square=”ts-button-3d” button_rounded=”ts-button-3d ts-button-rounded” button_pill=”ts-button-3d ts-button-pill” button_circle=”ts-button-3d ts-button-circle” button_size=”ts-button-normal” button_wrapper=”false” button_text=”Read More” button_change=”false” button_color=”#666666″ button_font=”18″ lightbox_group=”true” lightbox_effect=”random” lightbox_backlight=”auto” lightbox_backlight_color=”#ffffff” title_text=”Closing Remarks”]Dave describes a story of how was asked to solve a highly complex pulp and paper problem while an engineer at Kimberly Clark. The experts said it was going to cost $4M.

“I had to learn to adapt and improvise. I challenged my team to solve it using the resources we had. We ultimately fixed the problem at a fraction of the cost using the principles of Lean Six Sigma.”

David Bernd, Vice President of Economic Development at Covington/Newton County Chamber of Commerce[/TS_VCSC_Timeline_Single][TS_VCSC_Timeline_Single full_width=”false” featured_media=”image” featured_image=”15563″ lightbox_featured=”true” page_rtl=”false” featured_youtube_related=”false” featured_youtube_play=”false” featured_dailymotion_play=”false” featured_vimeo_play=”false” featured_media_height=”height: 100%;” featured_media_width=”100″ featured_media_align=”center” title_align=”center” title_color=”#7c7979″ icon=”transparent” icon_color=”#7c7979″ tooltip_css=”false” tooltip_position=”ts-simptip-position-top” button_align=”center” button_width=”100″ button_type=”square” button_square=”ts-button-3d” button_rounded=”ts-button-3d ts-button-rounded” button_pill=”ts-button-3d ts-button-pill” button_circle=”ts-button-3d ts-button-circle” button_size=”ts-button-normal” button_wrapper=”false” button_text=”Read More” button_change=”false” button_color=”#666666″ button_font=”18″ lightbox_group=”true” lightbox_effect=”random” lightbox_backlight=”auto” lightbox_backlight_color=”#ffffff” title_text=”Certification Process”]At the end of the day, the class takes the Lean Six Sigma Yellow Belt Certification exam to demonstrate knowledge and proficiency of key principles, techniques and tools.

Minimum score of 80% passing grade.

[/TS_VCSC_Timeline_Single][TS_VCSC_Timeline_Single full_width=”false” featured_media=”image” featured_image=”15566″ lightbox_featured=”true” page_rtl=”false” featured_youtube_related=”false” featured_youtube_play=”false” featured_dailymotion_play=”false” featured_vimeo_play=”false” featured_media_height=”height: 100%;” featured_media_width=”100″ featured_media_align=”center” title_align=”center” title_color=”#7c7979″ icon=”transparent” icon_color=”#7c7979″ tooltip_css=”false” tooltip_position=”ts-simptip-position-top” button_align=”center” button_width=”100″ button_type=”square” button_square=”ts-button-3d” button_rounded=”ts-button-3d ts-button-rounded” button_pill=”ts-button-3d ts-button-pill” button_circle=”ts-button-3d ts-button-circle” button_size=”ts-button-normal” button_wrapper=”false” button_text=”Read More” button_change=”false” button_color=”#666666″ button_font=”18″ lightbox_group=”true” lightbox_effect=”random” lightbox_backlight=”auto” lightbox_backlight_color=”#ffffff” title_text=”Celebration!”]Everyone passes the exam! Tired, but still smiling :). Overall, it was a great day of learning, doing, sharing, and leading!

[/TS_VCSC_Timeline_Single][TS_VCSC_Timeline_Single full_width=”false” featured_media=”image” featured_image=”15566″ lightbox_featured=”true” page_rtl=”false” featured_youtube_related=”false” featured_youtube_play=”false” featured_dailymotion_play=”false” featured_vimeo_play=”false” featured_media_height=”height: 100%;” featured_media_width=”100″ featured_media_align=”center” title_align=”center” title_color=”#7c7979″ icon=”transparent” icon_color=”#7c7979″ tooltip_css=”false” tooltip_position=”ts-simptip-position-top” button_align=”center” button_width=”100″ button_type=”square” button_square=”ts-button-3d” button_rounded=”ts-button-3d ts-button-rounded” button_pill=”ts-button-3d ts-button-pill” button_circle=”ts-button-3d ts-button-circle” button_size=”ts-button-normal” button_wrapper=”false” button_text=”Read More” button_change=”false” button_color=”#666666″ button_font=”18″ lightbox_group=”true” lightbox_effect=”random” lightbox_backlight=”auto” lightbox_backlight_color=”#ffffff” title_text=”Celebration!”]Everyone passes the exam! Tired, but still smiling :). Overall, it was a great day of learning, doing, sharing, and leading!

Kneeling: Peter Sherman – Instructor / Partner at Riverwood Associates and Scott Luton, Partner at Riverwood Associates[/TS_VCSC_Timeline_Single][/TS_VCSC_Timeline_Container][vc_column_text]

Course Survey and Results

[/vc_column_text][vc_row_inner][vc_column_inner width=”2/3″][vc_column_text]Instructor[/vc_column_text][vc_separator type=”transparent” position=”center” thickness=”1px” up=”2px” down=”2px”][vc_column_text]Knowledge of Subject 4.9 out of 5.0

[/vc_column_text][progress_bar_icon type=”normal” icon=”fa-star” size=”small” icons_number=”5″ active_number=”4.9″ icon_color=”#cccccc” icon_active_color=”#002f6a”][vc_separator type=”transparent” position=”center” thickness=”1px” up=”2px” down=”2px”][vc_column_text]Style of Teaching 4.8 out of 5.0

[/vc_column_text][progress_bar_icon type=”normal” icon=”fa-star” size=”small” icons_number=”5″ active_number=”4.8″ icon_color=”#cccccc” icon_active_color=”#002f6a”][vc_separator type=”transparent” position=”center” thickness=”1px” up=”2px” down=”2px”][vc_column_text]Enthusiasm 4.9 out of 5.0

[/vc_column_text][progress_bar_icon type=”normal” icon=”fa-star” size=”small” icons_number=”5″ active_number=”4.9″ icon_color=”#cccccc” icon_active_color=”#002f6a”][vc_separator type=”transparent” position=”center” thickness=”1px” up=”10px” down=”10px”][vc_column_text]Class[/vc_column_text][vc_separator type=”transparent” position=”center” thickness=”1px” up=”2px” down=”2px”][vc_column_text]Content 4.9 out of 5.0

[/vc_column_text][progress_bar_icon type=”normal” icon=”fa-star” size=”small” icons_number=”5″ active_number=”4.8″ icon_color=”#cccccc” icon_active_color=”#002f6a”][vc_separator type=”transparent” position=”center” thickness=”1px” up=”2px” down=”2px”][vc_column_text]Material/Handouts 4.9 out of 5.0

[/vc_column_text][progress_bar_icon type=”normal” icon=”fa-star” size=”small” icons_number=”5″ active_number=”4.8″ icon_color=”#cccccc” icon_active_color=”#002f6a”][vc_separator type=”transparent” position=”center” thickness=”1px” up=”2px” down=”2px”][vc_column_text]Pace 4.7 out of 5.0

[/vc_column_text][progress_bar_icon type=”normal” icon=”fa-star” size=”small” icons_number=”5″ active_number=”4.6″ icon_color=”#cccccc” icon_active_color=”#002f6a”][vc_separator type=”transparent” position=”center” thickness=”1px” up=”10px” down=”10px”][vc_column_text]General[/vc_column_text][vc_separator type=”transparent” position=”center” thickness=”1px” up=”2px” down=”2px”][vc_column_text]Pace 4.8 out of 5.0

[/vc_column_text][progress_bar_icon type=”normal” icon=”fa-star” size=”small” icons_number=”5″ active_number=”4.7″ icon_color=”#cccccc” icon_active_color=”#002f6a”][vc_separator type=”transparent” position=”center” thickness=”1px” up=”2px” down=”2px”][vc_column_text]Overall 4.9 out of 5.0

[/vc_column_text][progress_bar_icon type=”normal” icon=”fa-star” size=”small” icons_number=”5″ active_number=”4.9″ icon_color=”#cccccc” icon_active_color=”#002f6a”][/vc_column_inner][vc_column_inner width=”1/3″][vc_column_text]

Would you recommend course to others?

31 out of 31 said “Yes”.

Comments:

“Love it, love it, love it!”

“ The course was great. We covered a lot of material in an effective way.”

“The instructor was great. He wasn’t dry or boring, but very excited about sharing his knowledge with us.”

“Peter was very enthusiastic, warm, engaging, inclusive, and informative.”

[/vc_column_text][/vc_column_inner][/vc_row_inner][vc_column_text]

Thank You!

Peter Sherman – Instructor Riverwood Associates, Toni Ciccarello – SKC, and David Bernd – Newton County

Special thanks to our host, SKC Inc., and our sponsor, the Newton / Covington Economic Development Authority.[/vc_column_text][/vc_column][/vc_row]